(And how to minimize such risks...)

It's a nice sunny summer day or sprng morning and suddenly there's an audible crack in your sun facing window or door glass. Crack (or many) appear. When you ask from the supplier what's happening you'll get answer that this is "cracking due thermal stress in glass..."

If the glass breaks due to thermal stress it is not the indication of low quality of the glass - it is a phenomenon caused by the properties of the material itself and the the effect of surrounding environment. Therefore the thermal stress breaks are not cevered with the warranty of the glass. If the glass heats and the tmeperature differential reaches to critical levels, tensions (stress) in the glass may exceed critical threshold and glass breaks.

If the glass breaks due to thermal stress it is not the indication of low quality of the glass - it is a phenomenon caused by the properties of the material itself and the the effect of surrounding environment. Therefore the thermal stress breaks are not cevered with the warranty of the glass. If the glass heats and the tmeperature differential reaches to critical levels, tensions (stress) in the glass may exceed critical threshold and glass breaks.

Most common risk factors include objcects too close or against the glass and curtains (blinds etc.) which are too close to glass. But also the external shadows on the glass, additional safety, sunprotection and other type of foils attached to the glass.

Typical indication that occuring break is caused by thermal stress is 90-degree angle related to the glass edge and the crack itself is winding on the surface (so to say sinusoidal). In case of extreme tensions a fountain effect may appear so that many cracks start from one point.

What can one do...?

While planning curtains or blinds consider the safe distance from the glass - at least 50 mm from the glass internally. This way air can move and the glass surface does not heat too much.

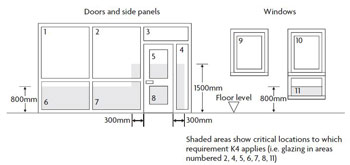

In architectural plans engineers must consider possible shadows of construction elements: roof edges, balconies etc. Large glazing such as high windows and doors should be with the safety glass according to building regulations. But in regards of thermal stress just laminated glass in not sufficient - thermally toughened glass should be used (also within the laminated glass if that is needed due to safety considerations).

In architectural plans engineers must consider possible shadows of construction elements: roof edges, balconies etc. Large glazing such as high windows and doors should be with the safety glass according to building regulations. But in regards of thermal stress just laminated glass in not sufficient - thermally toughened glass should be used (also within the laminated glass if that is needed due to safety considerations).

Only 100% sure solution to avoid thermal stress cracks is to use thermally toughened glass for all the glasses in insulated glazing unit (internal and external glass and in case of 3-glazing also the middle pane).

Special foils on the glass

- If applying special foil on the external surface (e.g. for security or sun protection) use thermally toughened glass for external pane. The internal (and middle pane in 3-glazing) are with the lower risks but some risk still remains.

- If applying special foil on the internal surface (e.g. for security, safety or smart foil) use thermally toughened glass for internal pane and we recommend thermally toughened pane for the middle pane in 3-glazing unit also. The external pane is with the lower risk but some risk still remains.

Also consider while planning your windows and doors, if instead of the additional special foils the similar desired functions could be achieved with the same type of glass e.g. sun protection LowE or safety or security glasses.

Blinds and curtains

If the blind system is integreted within the glazing unit (between the glasses) then -

- 2-glazing unit should be made of thermally toughened glasses both internal and external pane;

- 3-glazing unit the internal and middle pane should be thermally toughened glass. The external pane is with the lower risk but some risk still remains. Glazing manufacturer recommends all 3 panes to be thermally toughened.

Blind and curtains inside the room:

- Safe minimum distance between the glass and blinds/curtains is 50 mm. In this case thermally toughened glass is not needed (NB! Always consider the building regulations for safety!!!)

- If the blinds/curtains are closer than 50 mm use thermally toughened glass for internal pane. The middle pane in in 3-glazing unit and the external pane are with the lower risk but some risk still remains.

Read more from Wikipedia or find out with web search using "thermal break in glass" or "thermal stress glass breakage" or similar search words.

EST

EST ENG

ENG SWE

SWE Norwegian bokmål (Norway)

Norwegian bokmål (Norway)